Manufacturing

core processes are solid crystal, welding, dispensing, peeling, splitting, braiding, bagging and include production of 3528, 2835, 3030, 4040 and two-core to five-core high-power light sources

With light source power from 0.06W to 21W

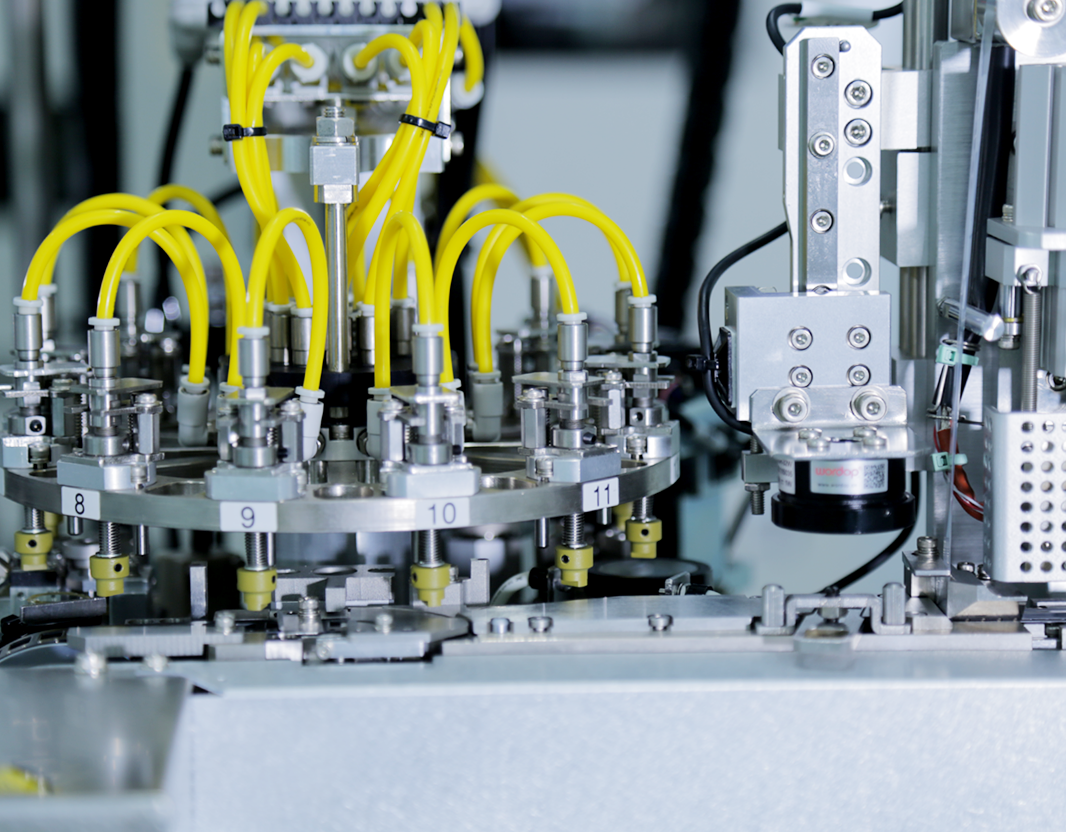

Surface Mount Technology (SMT)

high precision equipment allows reflow soldering and mounting components for PCB assemblies, including high power light sources, to a placement accuracy of 20 microns

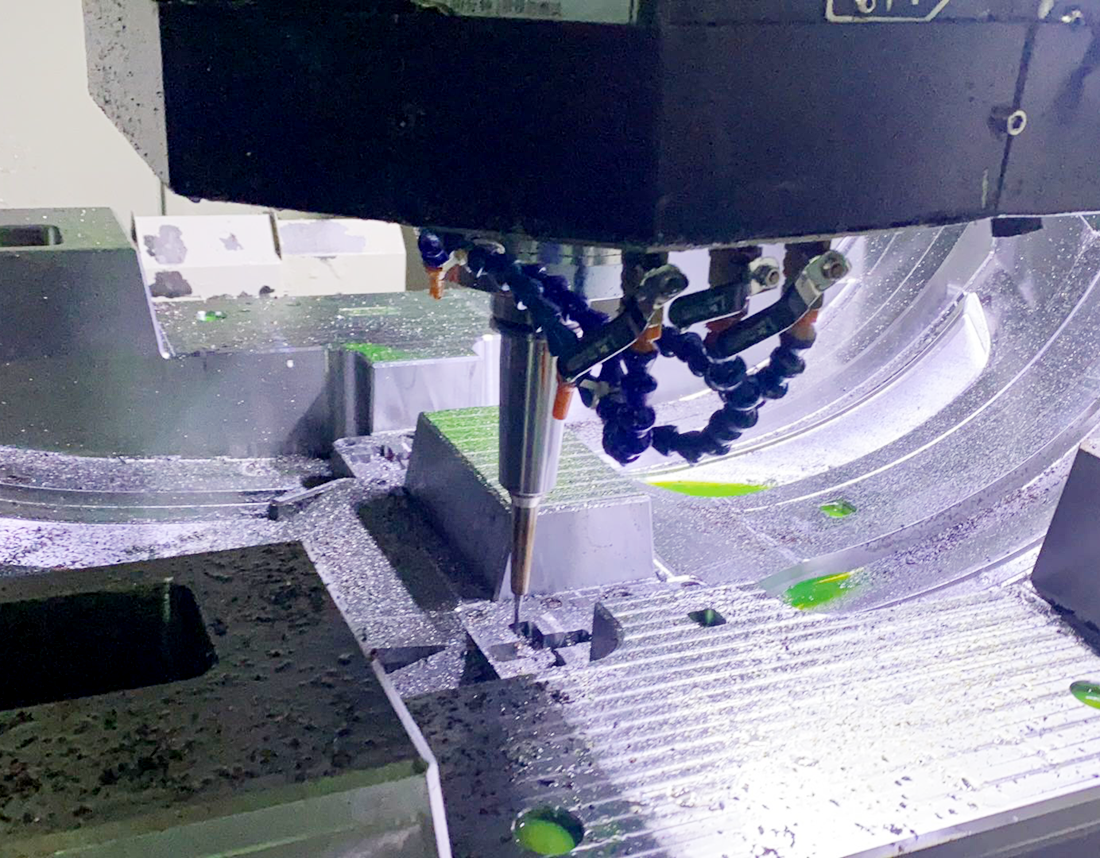

Tooling

is designed and manufactured in our Taizhou facility to ensure tool longevity and tolerance requirements for all component requirements and their efficient processing

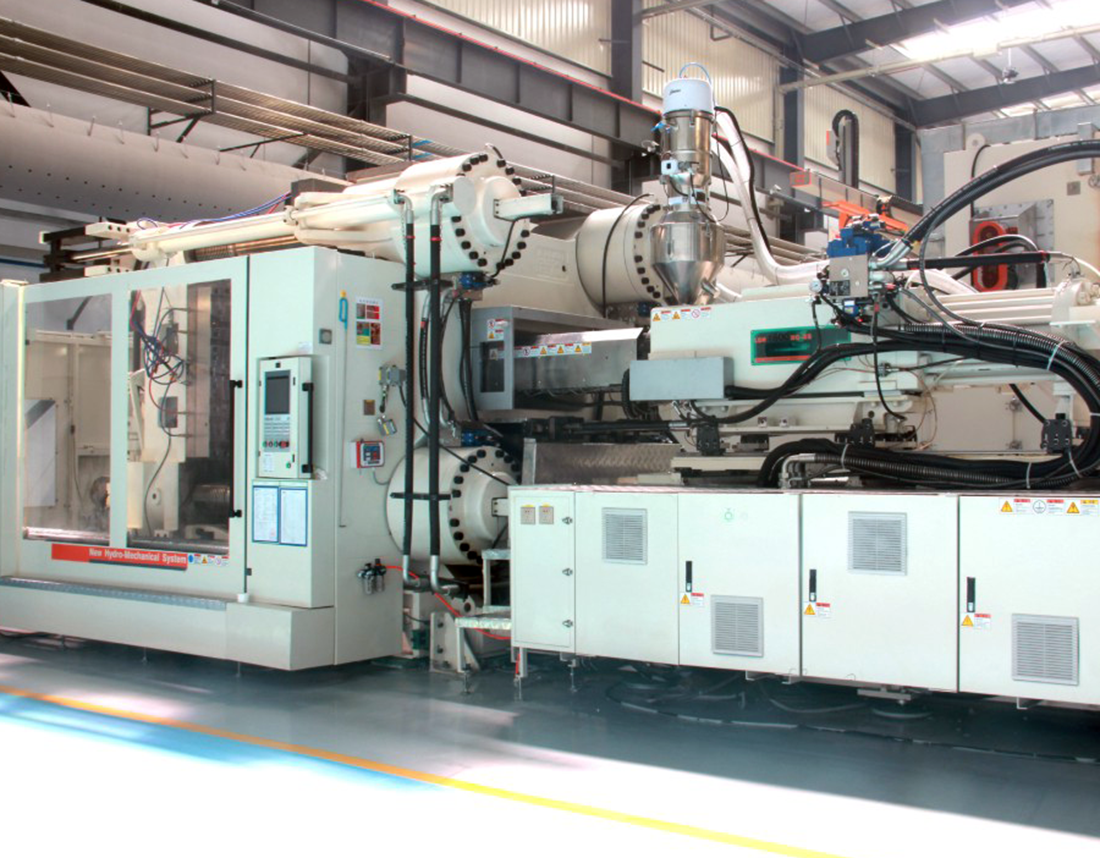

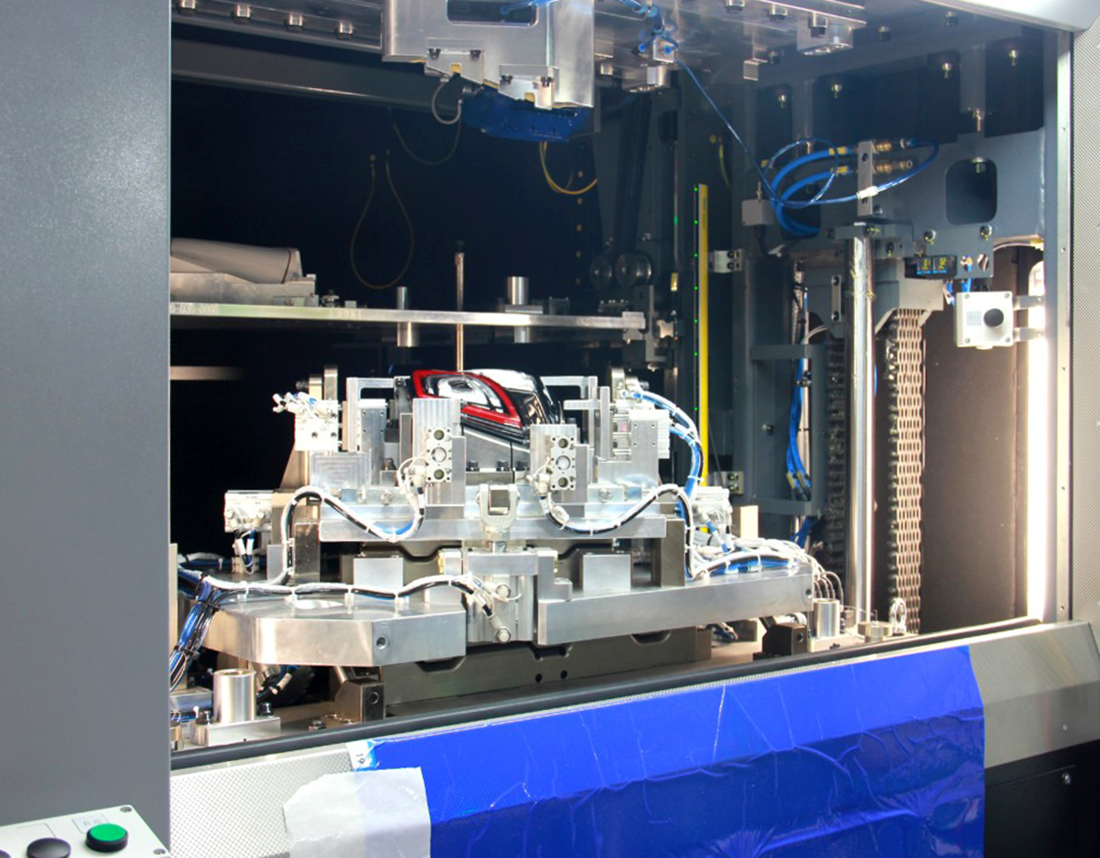

Injection Moulding

Surface treatment

includes aluminsing utilising Alumet equipment across all production plants, multiple automated hard-coating and anti fog coating lines as well as spray painting

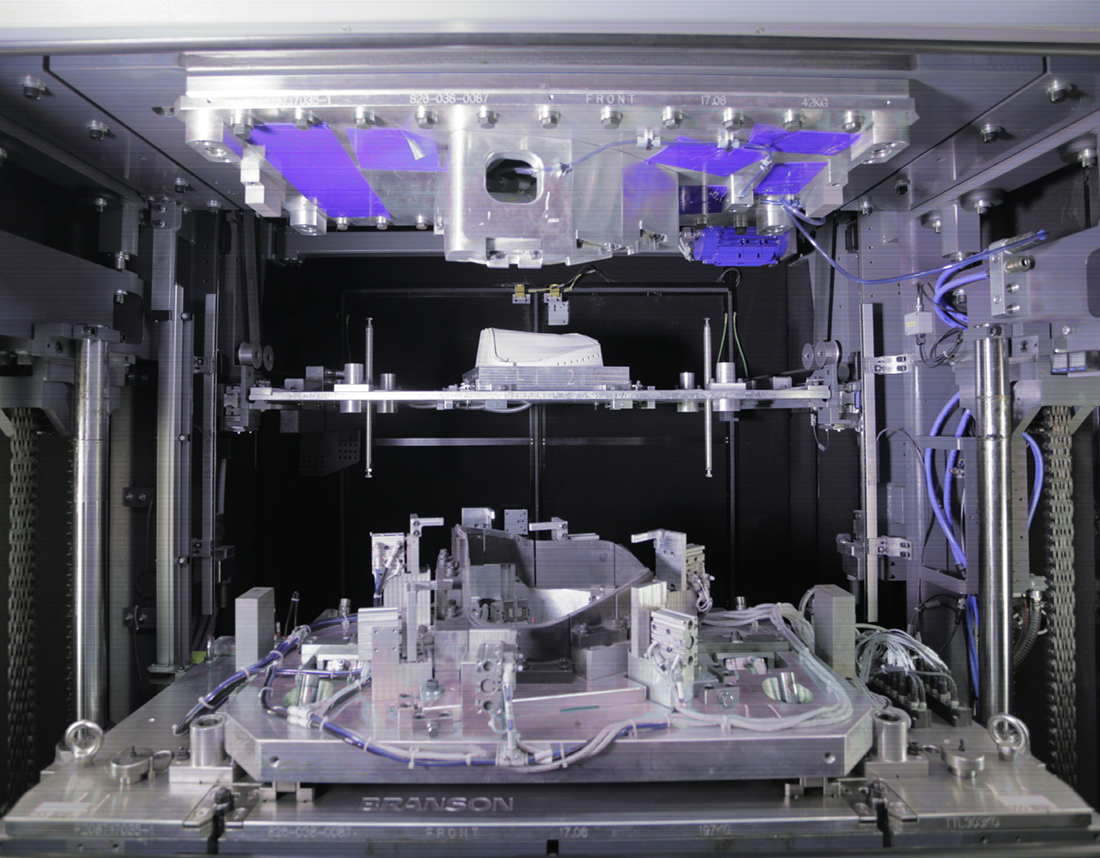

Assembly

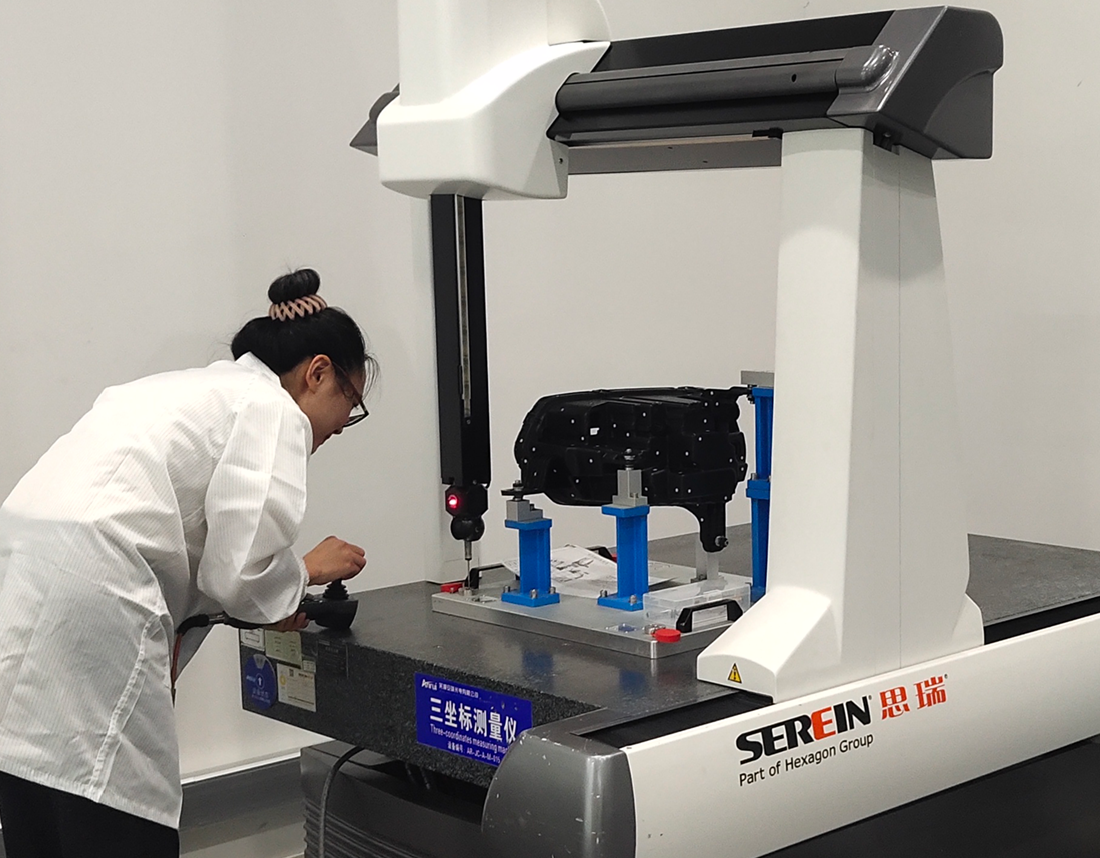

Measurement & inspection

are fully equipped with a range of CMM machines, laser scanning, optical spheres to control production processes